General Info

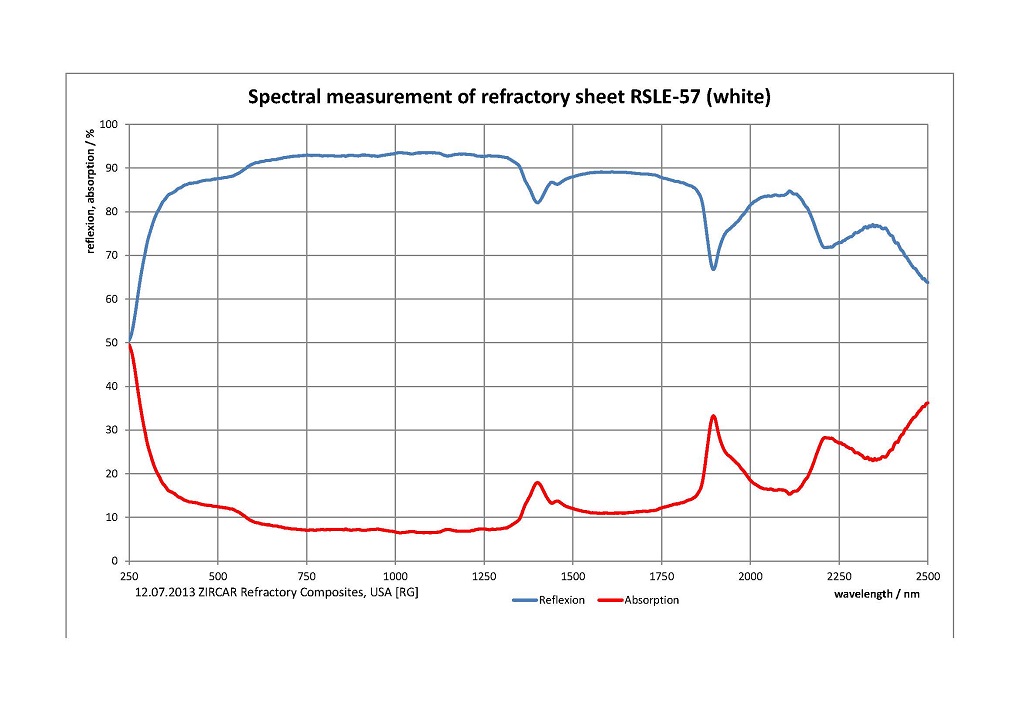

ZIRCAR Refractory Sheet Type RSLE-57 is a low expansion high strength reinforced silica matrix composite . This remarkable material was designed for use as a high strength insulator in induction hot press applications.

RSLE-57’s very low thermal expansion coefficient and high hot strength combine to give it thermal shock resistance not found in other structural ceramic matrix composite materials.

RSLE-57’s exhibits a very low coefficient of expansion 0.3 x 10-6 °C which provides remarkable resistance to the thermal shock up to 1200°C (2192°F)* in an oxidizing atmosphere and permits its use with rapid variation in temperature in that zone. Beyond 1200°C (2192°F) it transforms into a crystalline structure and becomes brittle. If the exceeded temperature is only localized, the material still retains its original high strength properties.

RSLE-57 also exhibits exceptional non-wetting properties when used in contact with molten aluminum making it useful in numerous molten aluminum contact applications.

RSLE-57 is 100% organic free and contains no refractory ceramic fiber. It is readily machined to precision tolerances with conventional tooling.

ZIRCAR Refractory Composites, Inc. (ZRCI) has developed a new material for the production of diamond segments that is far superior to all other high temperature, high pressure insulation. It has proven to be the best insulation material for Dr. Fritsch as well as other diamond segment sintering machines.

ZIRCAR Refractory Sheet Type RSLE-57 is an integral part of the production of hot pressed diamond segments. It is used as a separator to electrically and thermally insulate a metal frame from a graphite pack. It will see in excess of 1000°C (1832°F) with several thousand pounds per square inch compression without any surface deformation.

RSLE-57 is a low expansion, high strength reinforced silica matrix composite. Designed for use as a high strength insulator in induction hot press applications, it is ideal for any application, which requires a material with superior hot strength at temperatures as high as 1200°C (2192°F). RSLE-57’s very low thermal expansion coefficient and high density combine to give it thermal shock resistance not found in other structural ceramic composite materials. These properties give it much greater life in most hot pressing andinduction heating applications. This thermal stability also helps to increase the life of the graphite.

RSLE-57 will last many times longer than any calcium silicate, mica, asbestos or other hot press insulation, as well as produce a better segment. This will save you time, money, and leave you with less waste material to dispose of.

The majority of diamond segment manufactures in the US, Europe, India and South America has started using our material. They have stated that it will last 10 to 20 times longer in their most demanding hot press/sintering applications.

Properties

Other unique properties of RSLE-57 are:

-

A low thermal conductivity.

-

An excellent electrical insulation.

-

A high chemical purity.

-

An excellent resistance to corrosion (from molten metal and glass)

| Thermal Expansion Coeff. | |||

| Room Temp. to 800°C(1472°F) |

0.3 x 10-6/°C |

||

| Nominal Composition, wt% | |||

| SiO2 |

99.7 |

||

| Other Oxides |

<0.3 |

||

| Organics |

0 |

||

| Density, g/cc(pcf) |

1.4(90) |

||

| Porosity, % |

31 |

||

| Color |

White |

||

| Hardness, Durometer “D” |

87 |

||

| Charpy Impact Strength, ft-lb |

0.8 |

||

| Compressive Strength**, MPa(psi) | |||

| at 2.7% consolidation |

48(7000) |

||

| Modulus of Rupture**, MPa(psi) |

30(4300) |

||

| Thermal Conductivity** ASTM C-1113 | |||

| W/m°K(BTU/hr ft² °F/in) | |||

| 200°C(392°F) |

0.55(3.8) |

||

| 400°C(752°F) |

0.64(4.4) |

||

| 600°C(1112°F) |

0.61(4.2) |

||

| 800°C(1472°F) |

0.67(4.6) |

||

| 1000°C(1832°F) |

0.75(5.2) |

||

| Volume Resistivity, ohm-cm | |||

| ASTM D-257-93 |

7.5 x 109 |

||

| Dielectric Strength, volts/mil | |||

| ASTM D-149-95 |

43 |

||

| Linear Shrinkage, % ‡ |

Length |

Width |

Thickness |

| 24hrs @ 800°C(1472°F) |

0.1 |

0.1 |

0 |

| 24hrs @1100°C(2012°F) |

4.9 |

4.9 |

7.9 |

* Maximum use temperature is dependent on variables such as stresses, both thermal and mechanical, and the chemical environment that the material experiences.

** Properties expressed parallel to thickness.

‡ Properties expressed perpendicular to thickness.

Composition

- High Hot Strength

- Immune to Thermal Shock

- Fully Machinable

- Non RCF

Instructions

APPLICATION INFORMATION

MACHINING GUIDELINES

ZIRCAR Refractory Sheet Type RSLE-57 exhibits a uniformly bound fine-pore structure. It can be machined to precision dimensional tolerances with conventional carbide tooling following the guidelines outlined below:

| Cutting Tool |

Rotation Speed |

Feed Rate |

| Circular Saw Blade, Carbide tipped, 10″ diam. 24 teeth |

3450 |

15-20 ft/min |

| 4 Fluted Carbide End Mill |

1000-2000 |

15-20 ft/min |

Download the RSLE-57 Boards PDF File

SDS (in PDF format)

Other Information

AVAILABILITY

Please call, fax or e-mail for pricing and availability.

| Item # | Description |

| HM01 | RSLE-57 Boards, 610mm X 915mm X 3mm |

| HM02 | RSLE-57 Boards, 610mm X 915mm X 6mm |

| HM03 | RSLE-57 Boards, 610mm X 915mm X 8mm |

| HM04 | RSLE-57 Boards, 610mm X 915mm X 10mm |

| HM05 | RSLE-57 Boards, 610mm X 915mm X 12mm |

| HM06 | RSLE-57 Boards, 610mm X 915mm X 16mm |

| HM07 | RSLE-57 Boards, 610mm X 915mm X 20mm |

| HM08 | RSLE-57 Boards, 610mm X 915mm X 30mm |

| HM09 | RSLE-57 Boards, 610mm X 915mm X 50mm |

| HS01 | RSLE-57 Boards, 24″ X 36″ X 1/4″ |

| HS02 | RSLE-57 Boards, 24″ X 36″ X 3/8″ |

| HS03 | RSLE-57 Boards, 24″ X 36″ X 1/2″ |

| HS04 | RSLE-57 Boards, 24″ X 36″ X 5/8″ |

| HS05 | RSLE-57 Boards, 24″ X 36″ X 3/4″ |

| HS06 | RSLE-57 Boards, 24″ X 36″ X 1″ |

| HS07 | RSLE-57 Boards, 24″ X 36″ X 1 1/2″ |

| HS08 | RSLE-57 Boards, 24″ X 36″ X 2″ |

| HS09 | RSLE-57 Boards, 24″ X 36″ X 3″ |

| HS12 | RSLE-57 Boards, 24″ X 36″ X 1/8″ |

| HS20 | RSLE-57 Boards, 36″ X 48″ X 1/4″ |

| HS21 | RSLE-57 Boards, 36″ X 48″ X 3/8″ |

| HS22 | RSLE-57 Boards, 36″ X 48″ X 1/2″ |

| HS23 | RSLE-57 Boards, 36″ X 48″ X 5/8″ |

| HS24 | RSLE-57 Boards, 36″ X 48″ X 3/4″ |

| HS25 | RSLE-57 Boards, 36″ X 48″ X 1″ |

| HSFT1 | RSLE-57 Boards, 12” X 12” X 1/4” |

| HSFT2 | RSLE-57 Boards, 12” X 12” X 3/8” |

| HSFT3 | RSLE-57 Boards, 12” X 12” X 1/2” |

| HSFT4 | RSLE-57 Boards, 12” X 12” X 5/8” |

| HSFT5 | RSLE-57 Boards, 12” X 12” X 3/4” |

| HSFT6 | RSLE-57 Boards, 12” X 12” X 1” |

| HSFT7 | RSLE-57 Boards, 12” X 12” X 1.5” |

| HSFT8 | RSLE-57 Boards, 12” X 12” X 2” |

| HSFT9 | RSLE-57 Boards, 12” X 12” X 3” |

| HSFT10 | RSLE-57 Boards, 12” X 12” X 4” |

| HSFT12 | RSLE-57 Boards, 12” X 12” X 1/8” |

| HSRD1 | RSLE-57, 0.5” Diameter X 12” Rod |

| HSRD2 | RSLE-57, 0.75” Diameter X 12” Rod |

| HSRD3 | RSLE-57, 1” Diameter X 12” Rod |

PRICES ARE SUBJECT TO CHANGE WITHOUT NOTIFICATION AND ARE SUBJECT TO ZIRCAR REFRACTORY COMPOSITES, INC. TERMS AND CONDITIONS. ALL PRICES ARE F.O.B. FLORIDA, NY AND ARE IN U.S. DOLLARS