General Info

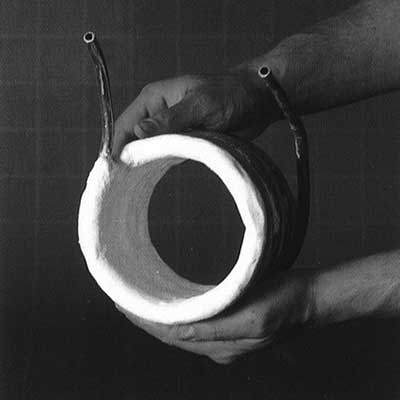

ZIRCAR Refractory Sheet Type RS-A is a tough ceramic fiber reinforced composite material available in standard boards and custom shapes made to customer specifications.

These products are made from Type RS-A Moldable. Type RS-A was developed as an asbestos board replacement for induction coil liners and molten metal transport, and contains no asbestos. Refractory Sheet Type RS-A is ideally suited for a wide range of high temperature, high thermal shock applications.

Type RS-A contains no organic binders and will produce no smoke or odors when heated.

Type RS-A products are available in 3 varieties: Type RS-A1 is dried to constant weight at 100°C(212°F). These products can be remoistened to impart moldablity. Type RS-A2 is fired for 3 hour at 600°C(1112°F) and fully cured. Type RS-A3 is fired, hardened with ZRCI AL-Hard at 5% pickup, and re fired. They are substantially higher in density than other ceramic fiber based moldable derived products.

Properties

| Typical Composition, % | |

| Al2O3 | 90 |

| SiO2 | 10 |

| Color | White |

| Organic Content, % | 0 |

| Specific Heat, BTU/lb°F (J/kg°K) | 0.25(1047) |

| Maximum Use Temp* C(F) | 1450(2642) |

| Thermal Conductivity,** (estimate) | |

| W/m°K(BTU/hr ft2 °F/in) | 0.65(4.5) |

| TYPE |

Type A1 |

Type A2 |

Type A3 |

| Density, gm/cm3(lb/ft3) |

1.6(100) |

1.6(100) |

1.7(105) |

| Porosity, % |

40 |

40 |

38 |

| Modulus of Rupture,** MPa(psi)

at room temperature |

3.4(500) |

3.9(560) |

9.1(1330) |

| Compressive Strength,** MPa(psi) at 10% deflection |

6.9(1000) |

9.7(1400) |

17.2(2500) |

| Hardness, Durometer “D” |

50 |

55 |

70 |

| Pullout Strength | |||

| (lbs on #10 sheet metal screws) |

30 |

50 |

90 |

| Moisture Content, % |

10 |

10 |

2 |

| Linear Shrinkage‡,16 hrs soak at 1200°C(2192°F) |

4 |

0 |

0 |

* Maximum use temperature is dependent on variables such as stresses, both thermal and mechanical, and the chemical environment that the material experiences.

** Properties expressed parallel to thickness.

‡ Properties expressed perpendicular to thickness.

Composition

Refractory Sheet Type RS-A is a tough ceramic fiber reinforced composite material available in standard boards and custom shapes made to customer specifications. It is ideal for applications up to 1450°C (2642°F). Type RS-A products are available in 3 varieties: Type RS-A1 is dried to constant weight at 100°C(212°F). These products can be remoistened to impart moldablity. Type RS-A2 is fired for 3 hour at 600°C(1112°F) and fully cured. Type RS-A3 is fired, hardened with ZIRCAR AL-Hard at 5% pickup, and re fired. They are substantially higher in density than other ceramic fiber based moldable derived products.

- Flexible and Strong

- Fully Machinable

- Non RCF

Instructions

SUGGESTED APPLICATIONS

- Induction Furnace components such as: channel melter components, coil liners, coreless induction components, splash and coil shields.

- Non-ferrous metal handling and transport as: spouts, troughs, and casting tips.

- Brazing separators and fixtures for jewelry-making as well as other industrial applications. The high Al2O3 content makes it resistant to sticking in many environments including molten metals.

- Ideal as high temperature gasketing material.

Download the RS-A Boards and Shapes PDF File

SDS (in PDF format)

Other Information

AVAILABILITY

RS-A Shapes are typically made to customer specification. Please contact ZRCI Sales Office for complete information.