General Info

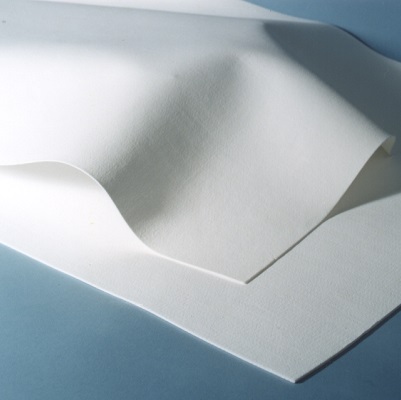

ZRCI Zirconia Felt Type RS-ZFELT is a mechanically interlocked textile structure composed of 4-6 micron diameter yttria-stabilized zirconia fibers. It is designed for uses in extremely corrosive environments and high temperatures. The felt is 100% fibers and contains no binders. It undergoes no phase transitions on temperature cycling and is a very effective thermal insulator, capable of use at temperatures exceeding 2000°C (3632°F). The stabilized zirconia composition permits the advantage of fibrous insulations to be extended into temperature regimes well above the melting temperatures of silica and alumina insulation materials.

RS-ZFELT is equally useful in strong oxidizing and reducing environments. It is not reactive to alkali vapors, salts or strong hot solutions and is not wet by most molten metals. It has low adsorption surface area and vapor pressure, 8×10-12 Torr at 1370°C (2500°F) makes it ideal to use in vacuum applications

RS-ZFELT retains its fibrous nature to 2480°C (4500°F) but loses its flexibility after being heated to about 1370°C (2500°F). Its specific heat increases from 0.13 BTU/lb °F to 0.18 at 2371°C (4300°F).

The thermal conductivity of RS-ZFELT is lower than that of the foam, bubble and grain forms of zirconia; thus, substitution of the fibrous insulation for these forms will improve thermal efficiency in existing installations.

Although yttria-stabilized zirconia is a semiconductor and becomes electrically conductive at high temperatures, it does not conduct with RF in the KiloHz frequency ranges.

RS-ZFELT is available in 18” X 24” sheets and in three standard thicknesses: .050”, .100”, and .150”.

Properties

| Properties (Nominal) | RS-ZFELT |

| Available Thickness, inch | .05, .100, or .150 |

| Bulk Porosity, % | 96 |

| Bulk Density, lb/ft3 (g/cm3) | 15 (0.24) |

| Tensile Strength, lb/in width | 0.6 |

| Melting Point, °C (°F) | 2593 (4700) |

| Maximum Use Temperature, °C (°F) | 2000 (3632) |

| Minimum Wrapping Diamater Before Breaking, inch | 0.25 |

| Vapor Pressure @ 2500°F, Torr | 8 x 10-12 |

| Linear Shrinkage, 1 hr. @ 1650°C Isothermal Soak, % | 5 |

| Specific Heat BTU / lb – °F | |

| @ 93°C (200 °F) | 0.13 |

| @ 2371°C (4300 °F) | 0.18 |

Composition

| Chemical Composition (Nominal) | |

| Oxide | Wt% |

| ZrO2 | 89+ |

| Y2O3 | 10 |

| Al2O3 | <0.01 |

| SiO2 | <0.02 |

Instructions

SUGGESTED APPLICATIONS

- Thermal insulating in induction heating, crystal growing, hot pressing, metal and glass melting applications

- Electrolytic cell separators as well as battery and fuel cell separators (KOH electrolyte)

- Excellent setter and fixture materials in powder metal applications

- Chemical and gas filtration media – hot alkalis and chlorides and in organic burnout type filters

- Diffusion burner membrane in gas fired heaters

- Hot isostatic press insulation in multiform insulation systems

RS-ZFELT Features

- Useful in high vacuum

- Temperature rating to as high as 2000⁰C (3632⁰F)

- Phase stabilized with 10 wt% Yttria

- High purity

- Low thermal conductivity (K)

- 100% inorganic, no off-gassing or odors

- Excellent in corrosive, oxidizing & reducing atmospheres

- Flexible to 1350⁰C (2462⁰F)

- High porosity

- Very light weight

- Wrappable

- Easy to cut

- Machinable

- Can be die cut

- Can be cemented or rigidized

Download the RS-ZFELT Zirconia Felt PDF File

SDS (in PDF format)

Other Information

AVAILABILITY

ITEM # DESCRIPTION

PX80 RS-ZFELT, 18” X 24” X .050”

PX81 RS-ZFELT, 18” X 24” X .100”

PX82 RS-ZFELT, 18” X 24” X .150”

Custom boards, shapes and preparations are available on request. Our forming processes, large Inventory of custom tooling and state of the art machining techniques allow a wide variety of sizes and shapes to be made. Special geometries such as disks, rings and custom-machined shapes can be fabricated. Tight tolerance machining, compositional variations and the application of surface, rigidizers and hardening agents are available. Please contact us with your special requirements.