Users Guide for Luminar Moldable Sheet (RS-DD)

Luminar Moldable Sheet (otherwise known as ZRCI RS-DD). Is and advanced material for glass slumping and fusing. No other mold making material is as strong, light weight, versatile, durable, and easy to use. Luminar Moldable Sheets are sold as semi-rigid sheets available in several thicknesses and dimensions. The thinner sheets will posses the most moldability, while the thicker sheets possess the most strength.

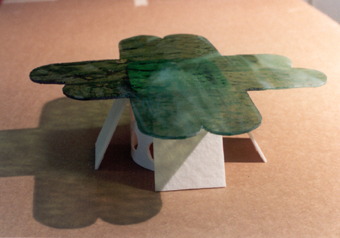

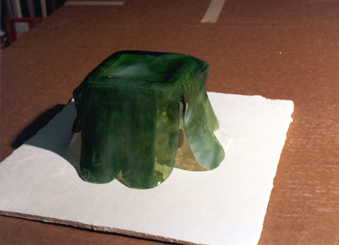

Luminar Moldable Sheets have the ability to become pliable while wet with water. The wet sheet can be formed into any variety of shapes and textures. When dry, these sheets become rigid and regain its original strength in the newly formed shape.

Upon firing, a small amount of organic binder will burn out of sheet and the ceramic strength will fully develop, making the resulting mold three times as strong as the mold in its green, unfired state. After it is fired, the sheet will lose its ability to be molded when wet. Luminar Moldable Sheets are resistant to thermal shock. These sheets have been proven to allow firing rates of 130⁰F/min in a stationary studio kiln with 1/8” glass.

SELECTING LUMINAR MOLDABLE SHEET:

Selection of the best thickness of Luminar Moldable Sheet to use is mostly a matter of balancing the strength and the degree of curvature to be developed in the final piece. When molding a flat piece of Luminar Moldable Sheet into a curved shape you will observe a certain amount of “puckering” or folding. This effect will be more pronounced when using thicker sheets because the difference in the radius between the inner and outer surfaces of the sheet is greater. Using the thinnest thickness Luminar Moldable Sheet will reduce any difficulty. If these folds become unavoidable in the molding process, excess material can be cut away and a seam can be created. Methods of cutting this material are listed below. When wet, Luminar Moldable Sheet may be firmly squeezed and held together at the seam to result in a firm bond upon dryig. The seam can be dressed and burnished with a damp cellulose sponge. If necessary, any irregularities may be corrected using Luminar Mold Mix 6, a ceramic paste which can be used to smooth the seam.

CUTTING LUMINAR MOLDABLE SHEET:

Luminar Moldable Sheet may be cut using a utility of an X-Acto knife when wet or dry, although cutting is generally easier when the material is wet.

WETTING LUMINAR MOLDABLE SHEET:

After the desired shape is cut, the Luminar Moldable Sheet is ready to bet wet with water. Fill a shallow tray with warm water and immerse your sheet completely. The sheet should be fully submerged. The table below describes the soak times for sheets of each thickness:

| Sheet Size | Soak Time | Process Time |

| 0.02 Inches Thick | 50 seconds (apply only to 1 side of the sheet) | 1 Minute |

| 0.04 Inches Thick | 2 Minutes Each Side | 5-6 Minutes |

| 0.08 Inches Thick | 4 Minutes Each Side | 8-10 Minutes |

| 0.12 Inches Thick | 6 Minutes Each Side | 12-15 Minutes |

After the sheet is wet test it for flexibility. The moistened sheet should feel like wet leather. If the sheet is not flexible enough, apply more water. If the sheet is overly moist blot excess water with a paper towel. Any unused wet sheet can be dried and stored flat for re-use.

APPLYING LUMINAR MOLDABLE SHEET TO A PATTERN:

Luminar Moldable Sheet will bond quite firmly to any surface, even glass. To assure easy removal from a pattern, a very thin coat of petroleum jelly should be applied to the pattern. Once the sheet is laid on the pattern it must be held firmly in order to accurately replicate the contours of the model. Clothespins are helpful for holding sheet in place while it dried on the pattern.

DRYING LUMINAR MOLDABLE SHEET:

Luminar Moldable Sheet should be left to air dry. If the drying process needs to be accelerated the sheet can be warmed in the kiln to 200⁰F. Take care that the pattern will be able to withstand this heating. Once dried, Luminar Moldable Sheet will regain its original rigidity.

PREPARING TO FIRE:

Prior to firing, finishing can be done on the mold. This is easily done using a damp cellulose sponge or finger. The Luminar Moldable Sheet surface may be burnished until it shines. If the mold is to be used for fusing, apply a coat of Luminar Alumina Coat to avoid sticking. This step must be repeated each time the mold is fired for fusing.

FIRING LUMINAR MOLDABLE SHEET:

No special precautions are necessary to fire a Luminar Moldable Sheet mold. As mentioned previously, the firing process can proceed at very rapid rates with no difficulty. However, in the event that the glass is fairly heavy, it will be desirable to pre-fire the mold. This step will allow the sheet to develop its ceramic strength before it is loaded with glass.

NOTES ON USING LUMINAR MOLDABLE SHEET FOR FUSING:

Luminar Moldable Sheets can be used as a fusing surface for most glass, with the exception of “Wasser Glass” which has a pronounced tendency to stick to these sheets. It is crucial that the surface of the sheet be treated with a coat of Luminar Alumina Coat each time the sheet is fired to avoid sticking. Luminar Alumina Coat can be applied with a nylon brush and a wet sponge can be used to smooth the surface. Fire the sheet to fusing temperatures no faster than 15⁰F/min on a flat ceramic kiln shelf. The slow firing will avoid warping and help to develop the ceramic strength of the sheet. Shelf supports can be formed out of these sheets as well.